FlexiBowl® ISO 5 Cleanroom Compatible

The versions of Flexibowl® certified for use in ISO Class 5 controlled environments as defined by ISO 14644-1 maintain all the functions of the standard FlexiBowl®.

Main features:

- Pneumatic components specific for cleanroom use;

- Back-lighted glass plate

- Perforated top screen to favor laminar flow

- Available for Flexibowl® 500/650/800 feeding systems

- Product contact surface suitable for cleanroom use

- Cap in natural white polyethylene to prevent component jams at center

Want to learn more?

Contact us for a free estimate!

Main Sectors of Application

From pharmaceuticals to aerospace, many sectors use cleanrooms for their assembly systems.

F.A.Q.

A cleanroom is a controlled-atmosphere space (air pressure, relative humidity, airborne particles within strict limits), which should not be confused with a hypobaric chamber (controlled pressure) or with sterile rooms (controlled microbiological load) or anechoic chambers (electromagnetically- and sound-isolated).

Cleanrooms operate on the principle of forced recirculation of super-filtered air in a sealed space. The system that achieves this condition is composed of high-volume fans operating at low speeds that introduce a laminar flow of previously filtered air into the space through ceiling vents.

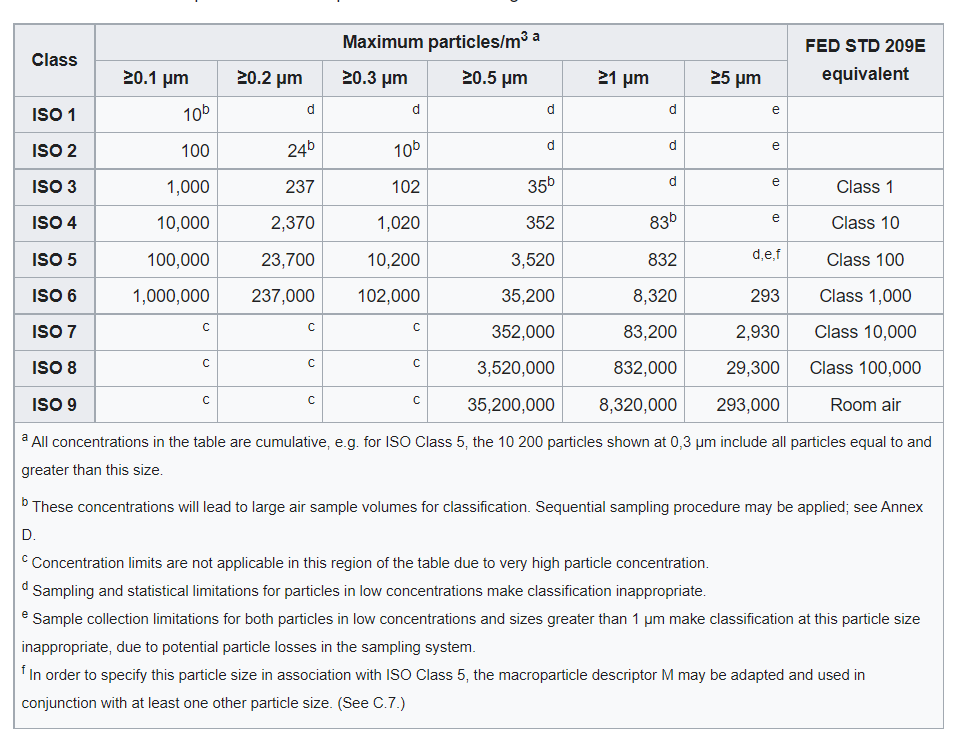

Cleanroom classification

Cleanroom classification takes into account the number of microparticles of various dimensions in a given volume of air; the lower the number of particles suspended in the air, the ‘cleaner’ the cleanroom.

Cleanrooms: ISO 14644-1 (source: Wikipedia)

The EN ISO 14644-1 standard establishes 9 classes (from 1 to 9) for the cleanliness of the air in controlled environments and for each class defines the maximum quantity of particles of different diameters (from 0.1 to 5.0 μm) admissible per cubic meter of sampled air.

The class of reference for biological applications is ISO 5 (formerly Class 100, FED-STD-209E) which sets an upper limit of 3520 units per cubic meter of sampled air for particles of diameters equal to or greater than 0.5 μm.

The versions of FlexiBowl® for cleanroom use incorporate a series of modifications that make it suitable for use in cleanroom environments classified ISO 5 and higher.

In detail:

- Back-lighted glass plate

- Pneumatic components specific for cleanroom use

- Perforated top screen to favor laminar flow

The characteristics of the materials used in the cleanroom-certified versions of Flexibowl® – stainless steel, glass, and natural polycarbonate – are appropriate for use in controlled atmospheres even if subject to friction and abrasion.

Cleanrooms are used in many sectors of the economy, for instance in the medical, chemical, pharmaceutical, and microelectronics industries.

Many companies currently look to updating their systems by adding cleanroom capability: from food and beverage to optics, from cosmetics to biology, to aerospace.

Cleanroom technology is also used by companies in the composite-fiber, mechanical construction, automotive, and plastics-molding sectors.

Many of the industrial robots now available are certified compliant with current legislation and the ISO-14644 standards and are therefore verified for use on assembly lines in cleanroom environments.

Some examples by manufacturer:

- Universal Robot UR3E, UR5E, UR10E;

- Denso Series VS 6-axis

- Kawasaki Series MC004N, MC004V, MS005N for medical and pharmaceutical applications and Kawasaki Series NTS and Series TTS for microelectronics applications

- FANUC LR Mate 200iD/4SC, LR Mate 200iD/7C, LR Mate 200iD/7LC;

- YASKAWA CSDA10F;

- ABB IRB 1100 and IRB 1300

- KUKA LBR iiwa CR, KR 10 R1100 CR, KR 210 R2700 prime CR, KR CYBERTECH nano Pack, KR 10 R900 CR, KR 6 R700 CR, KR 6 R900 CR

- Mitsubishi Electric Series RV-F Robot and RH Series Scara Robot;

- Stäubli TX2-60, TX2-60L, TX2-90, TX2-90L, TX2-90XL

- Epson SCARA (Series LS, RS, G); 6-Axis (VT, Series C)

- Omron SCARA Robots eCobra 500, 600, 800 Lite/Pro/Standard and Viper 650, 850

- Nachi Fujikoshi Series SC.

ISO 5 Cleanroom-Compatible Flexibowls®

Download 3D Step Files

| Component Dimensions | 1mm | ◆◆◆◇◇ | 250mm |

| Component Weight | 1g | ◆◆◆◇◇ | 250g |

| Bulk Feeder | 1,5L | ◆◆◆◇◇ | 40L |

| Maximum Load | 1Kg | ◆◆◆◆◆ | 7 Kg |

Discover all the FlexiBowl 500 Options

| Component Dimensions | 1mm | ◆◆◆◆◇ | 250mm |

| Component Weight | 1g | ◆◆◆◆◇ | 250g |

| Bulk Feeder | 1,5L | ◆◆◆◆◇ | 40L |

| Maximum Load | 1Kg | ◆◆◆◆◆ | 7 Kg |

Discover all the FlexiBowl 650 Options

| Component Dimensions | 1mm | ◆◆◆◆◆ | 250mm |

| Component Weight | 1g | ◆◆◆◆◆ | 250g |

| Bulk Feeder | 1,5L | ◆◆◆◆◆ | 40L |

| Maximum Load | 1Kg | ◆◆◆◆◆ | 7 Kg |

Discover all the FlexiBowl® 800 Options

Compatible with All Robots

Discover all the available Plugins

Our plugins are fully documented for a vast range of robots and PLCs.

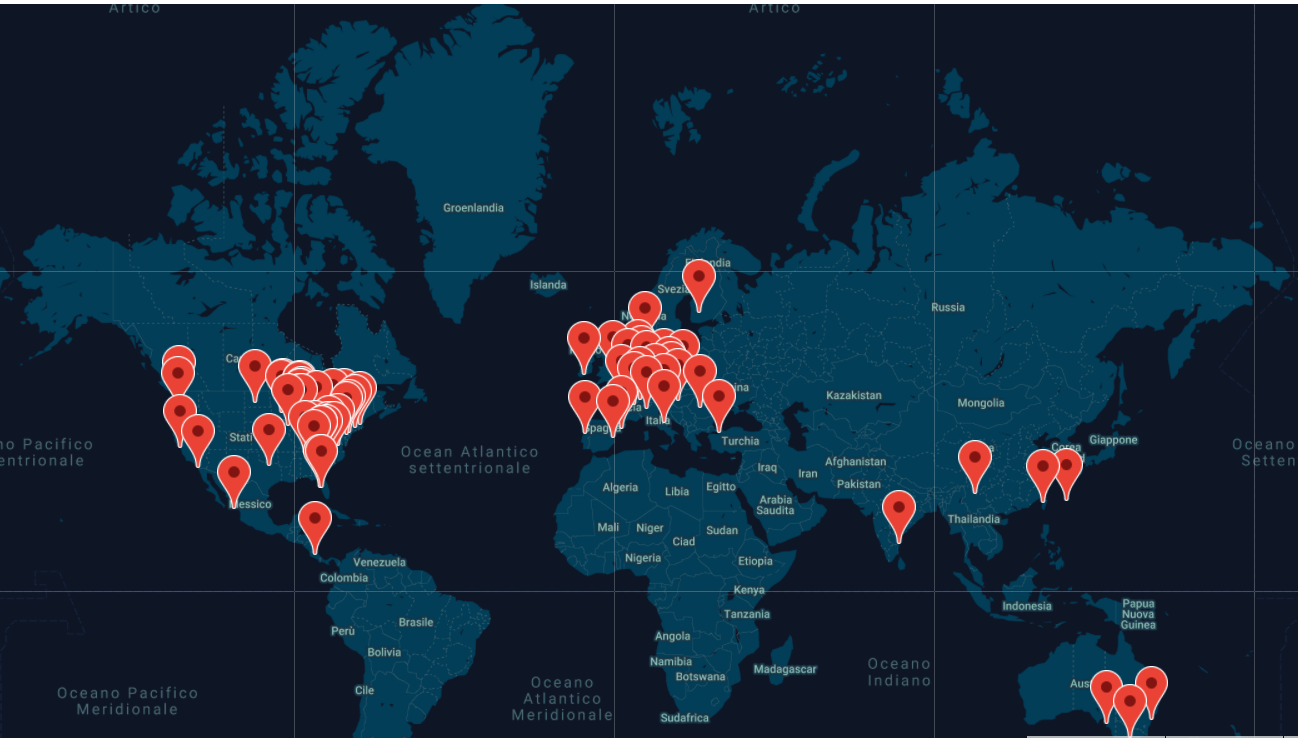

Find a Distributors

Find your nearest Distributor

FlexiBowl® is supported by a capillary network of qualified distributors and installers that spans 40 countries worldwide.

Professionals you can rely on for support during design and configuration and for assistance for optimizing your cleanroom system.

Find the best distributor for your needs.