History of Flexible Feeding Systems

Market evolution has always been influenced by choices made with regard to flexibility, unit production cost and productivity.

In the middle of the 1960s, market competition became increasingly intense, and production cost was the chief concern. High volumes of individual products were sold to the “mass market”, enabling a policy emphasizing economy of scale and cost efficiency.

Today quality is becoming a priority.

Mass customization defines the market trend; meeting the needs of each individual customer is the core competitive advantage of this policy.

Mass customization provides products that match customers’ needs much more effectively than standardized products.

Consumers expect personalization of a standard product (e.g., different colors of the same mobile phone) as well as short delivery times and high quality products and services.

Companies need to adapt to the environment in which they operate, allowing flexibility in their operations to satisfy different market segments.

This is essential for achieving the shortest time to market, which is one of today’s key success factors.

Types of Automation Assembly Systems

Lean Automation

- A process that focuses on maximizing labor and material flow efficiency with the support of semi-automated tools, often arrayed in modular cells. Labor efficiency and cost containment are the main goals.

Flexible (“Agile”) automation

- Automation that can be easily reconfigured to process different products and processes, thus aligning production with variable market demands. Fast changeover, batch control and process integration are the main goals.

Fixed automation

- Automation that is designed to perform fixed and repetitive sequences of operations on unchanging components and assembly processes. Low unit costs, high throughput and process integration are the main goals.

This is why flexible manufacturing systems and flexible assembly systems are becoming the leading technology used by industrial companies today.

The goal is to produce quality products that satisfy customers in the shortest time possible at the lowest cost attainable.

Manufacturers must meet customers’ needs in order to be leaders in the market. For those situations where dedicated solutions cannot be used, applying innovative techniques has resulted in the development of a flexible machine that can perform several operations.

In most cases, part feeding is still done with vibratory bowls, a dedicated solution with good value but short lifecycle. Its usefulness depends on product variation, because if product changes become necessary, the vibratory bowl cannot be used for other applications and loses any residual value.

Flexible part feeding solutions are of primary importance in companies today.

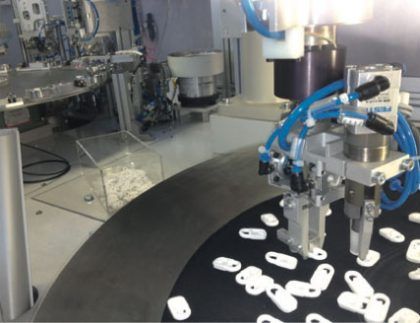

The flexible part feeding system FlexiBowl®, developed by Ars Automation, has incorporated several innovative features, offering higher performance with less cost than traditional part feeding solutions.

When feeding of entire product families is required, the FlexiBowl® solution is even more appropriate.

Entire families of components can be fed using the same system. Efficiency is guaranteed by superior performance and low failure rate, even when parts have burrs or dimensional and quantity variations.

Advantages of Flexible Part Feeding Systems

- Flexible solutions can be easily reconfigured to accommodate production changes. With the FlexiBowl® solution, this can be done quickly and inexpensively. With traditional part feeding solutions, major modifications are necessary even with small product variations.

- Part picking does not require specific part orientations. The vision system can locate parts with different orientations. Products with complex geometries can be handled without problem as well. In addition, flexible part feeding systems are convenient since they allow handling of different products.

- The performance and efficiency of FlexiBowl® systems remains constant and does not decrease over time.

- The efficiency of flexible feeding solutions is much higher than traditional parts feeders, and FlexiBowl® allows the system to be more productive, requiring less assistance and maintenance over time.

- FlexiBowl® reduces potential risks when new projects are evaluated. Flexible systems can be easily tested in advance and can accommodate process variations even during the development phase of new projects.

- FlexiBowl® entails lower costs when changing from one part to another, which improves capital utilization.

- Where FlexiBowl® has been installed, companies have realized lower direct labor costs due to the reduction in the number of workers.

- Flexible part feeders allow reduced inventory as a result of increased precision during planning and programming.

- Since it is automated, a flexible parts feeder allows reduction of errors, reworking, repairs and rejects.

Flexible Part Feeding Systems applications

With the advantages of the FlexiBowl® concept of flexibility, applications have been developed in many different areas, including cosmetics, the automotive industry and the medical field.

The FlexiBowl® system is particularly suited for handling a large variety of cosmetic products including mascara, lipsticks, compacts and brushes, to name just a few of the areas that are already using FlexiBowl® in their assembly lines.

As an example, FlexiBowl® is used to feed mascara brushes to a mascara cap-filling machine. FlexiBowl® is ideal for handling cylindrical parts, such as those used in mascara production. Parts do not get scratched, and entire families of parts can be handled without problems regardless of size, geometry and color.

In the production of compacts, the compact container is composed of a variety of components that can be assembled automatically. For example, if it is necessary to load the opening button on a powder compact container, the system must be able to feed a number of different components. In addition to the different geometries of the parts, difficulties lie in the tendency of parts to tangle. FlexiBowl® reliable avoids such difficulties.

Silicon and rubber parts are often present inside medical disposable products, and traditional part feeding solutions do not always provide enough reliability to handle these parts properly. FlexiBowl® prevents jamming during assembly, ensuring efficient and reliable operation.

FlexiBowl® is reliable even in harsh environments due to its simple construction. The system is currently used successfully by companies in the automotive industry who produce plastic, rubber and foam parts, and who need a flexible feeding system that works in coordination with robotic and vision systems.