This case study explores the transformation of a manufacturing company's bolt quality inspection and palletizing process with cutting-edge automation solutions.

Case Study: Flexible Feeding System for quality inspection and palletizing process

The Challenge

- Develop an automated island capable of handling both inspection and palletizing processes within a compact layout.

- Utilize a singular flexible feeder to handle a variety of bolt types.

- Establish a collaborative and safe workspace for human and machine interaction.

- Enhance overall performance and minimize error rates.

The Solution

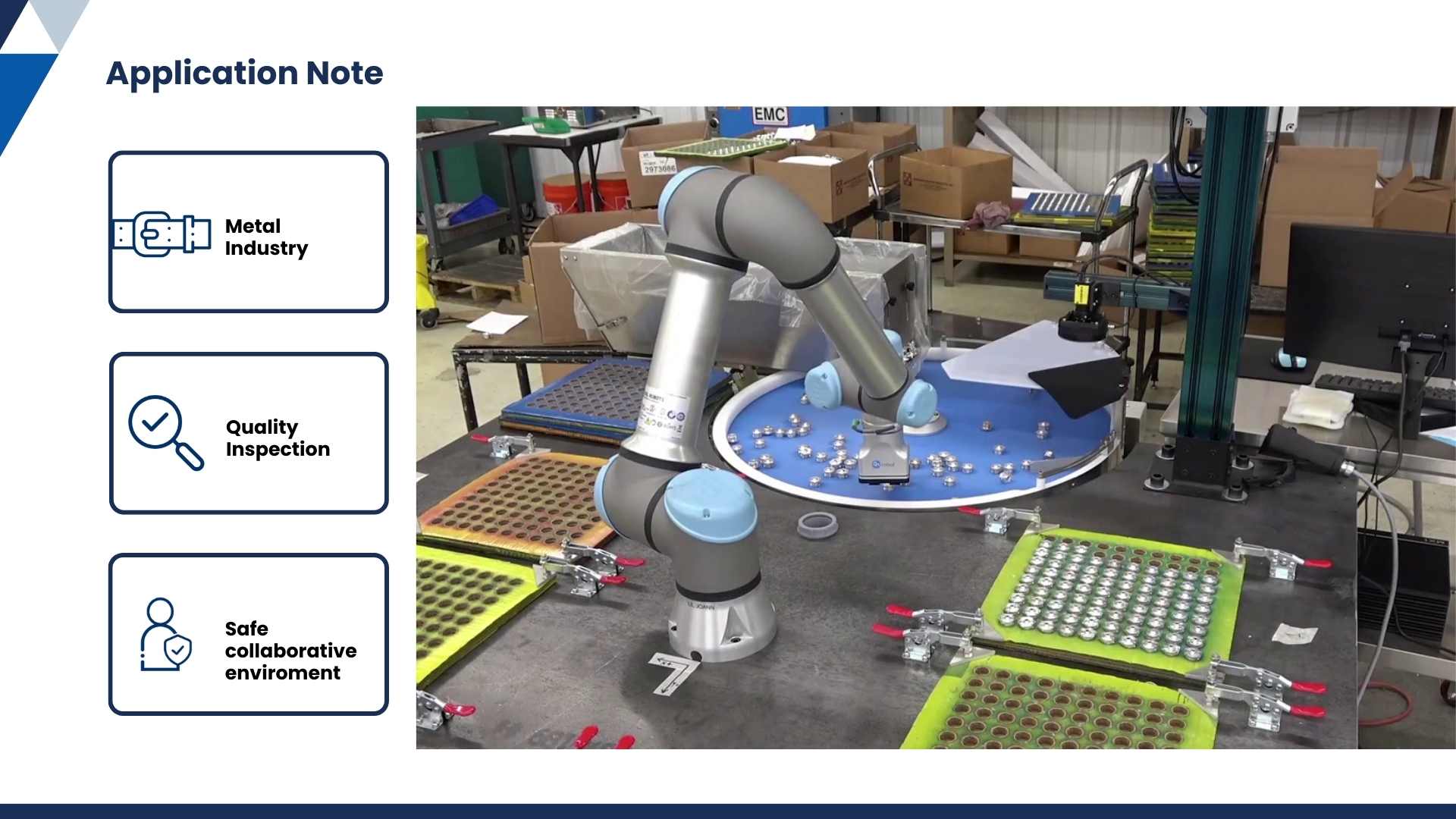

- Integration of the FlexiBowl® 650 parts feeder for handling a variety of bolt types, providing space-saving and seamless integration into the production line for consistent and uninterrupted component flow.

- Employment of Universal Robots collaborative solution to enhance efficiency and accuracy in tandem with human operators, improving workflow in quality inspection and palletizing tasks.

- Seamless integration into existing production lines, thanks to the flush-mount design of the system, contributing to a well-organized and compact robotic area.

- Achievement of a smooth and efficient operation by handling various bolt types and ensuring a consistent flow of components, thereby optimizing the inspection and palletizing processes.

The Benefit

- Automated Island Creation: Engineered a compact and optimized automated island to centrally manage various tasks, streamlining the handling and processing of diverse bolt types within a singular, efficient system.

- Performance Enhancement: Achieved a notable increase in productivity by facilitating continuous, versatile handling of different bolt types, thus boosting the overall bolt processing rate without necessitating frequent system adjustments.

- Quality Improvement: Implemented advanced vision systems and precise robotic movements, significantly elevating inspection accuracy and ensuring the delivery of only high-standard bolts, thereby drastically reducing error rates.

- Safe and Collaborative Workspace: Incorporated a space-efficient design and safety features for human-robot interaction, fostering a safer, more collaborative work environment and maximizing the effective use of available space.

Abstract

In the rapidly evolving metal fastener industry, a leading manufacturer enhanced its bolt quality inspection and palletizing process by integrating the FlexiBowl® 650 and a collaborative cobot by Universal Robots. This solution adapted seamlessly to various bolt types and sizes within a compact workspace, significantly increasing productivity and maintaining high quality. The cobot worked alongside human operators, ensuring a safer and more efficient production line. The result was a notable increase in processing rates, precision in quality inspections, and optimal utilization of space, demonstrating the transformative impact of advanced automation in meeting the industry's complex demands.