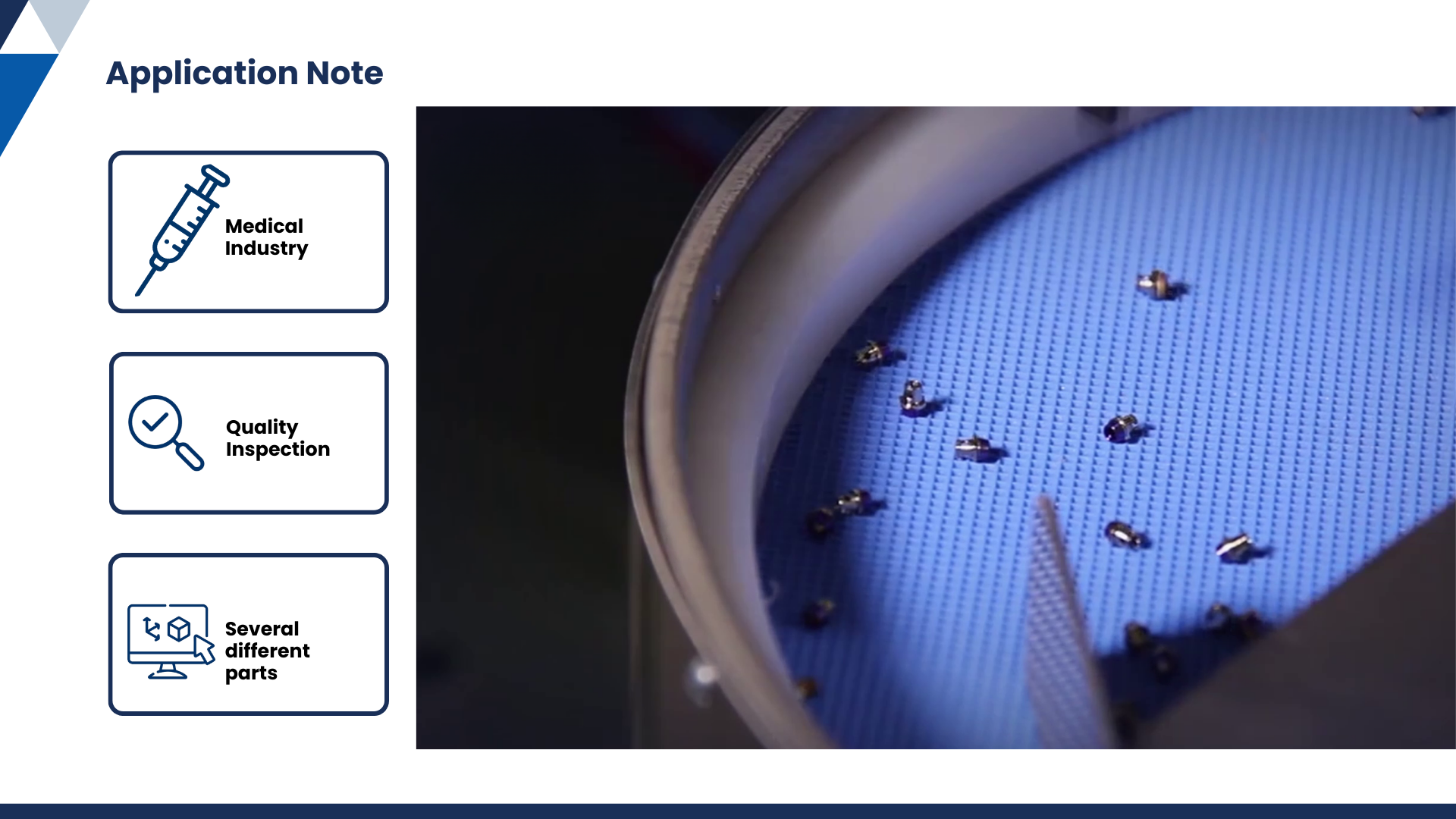

Feeding and Quality Inspection of Dental Screws and Metallic Components with FlexiBowl® 350 and 800.

Flexible Solution for Quality Inspection and Feeding of Metallic Components in Various Sizes and Shapes.

Our Partner

EasyControl: specialized in machine vision solutions for the industrial sector since 1998, with a strong international presence. It offers advanced inspection systems, delivering customized solutions for every project, supported by a wide range of installed equipment.

The challenge

- Managing metallic components with complex geometries and variable dimensions without requiring numerous machines with different setups.

- Ensuring uninterrupted handling of components prone to overlapping.

- Optimizing production space through a compact and modular layout.

The solution

- FlexiBowl® 350: precise and gentle feeding for small parts with complex geometries.

- FlexiBowl® 800: stable and reliable handling of larger and irregularly shaped components.

- EPSON Robot: ensures fast and accurate movements for part positioning in the inspection area.

- Advanced vision system: for geometric control and defect detection.

- Compact and modular layout: ideal for production environments with limited space.

The benefit

- Easy Integration with EPSON robots and the vision system for a seamless process.

- Enhanced productivity through reduced downtime and continuous operation.

- Modular and compact layout, ideal for limited production spaces.

- Maximum flexibility for handling components of various sizes without manual adjustments or complex reconfigurations.