An advanced automated solution to swiftly manage the separation, singulation, and orientation of a large volume of parts

Case study: Advancing Precision in Product Feeding - Streamlining Laser Marking Operations for Complex and Delicate Parts

The Challenge

- Implement an automated system to optimize laser marking operations.

- Gently feed delicate products, minimizing damage and ensuring precise handling.

- Ensure accurate product insertion into the marking machine to reduce errors and enhance product quality.

- Develop a flexible system within an optimized layout for streamlined efficiency.

The Solution

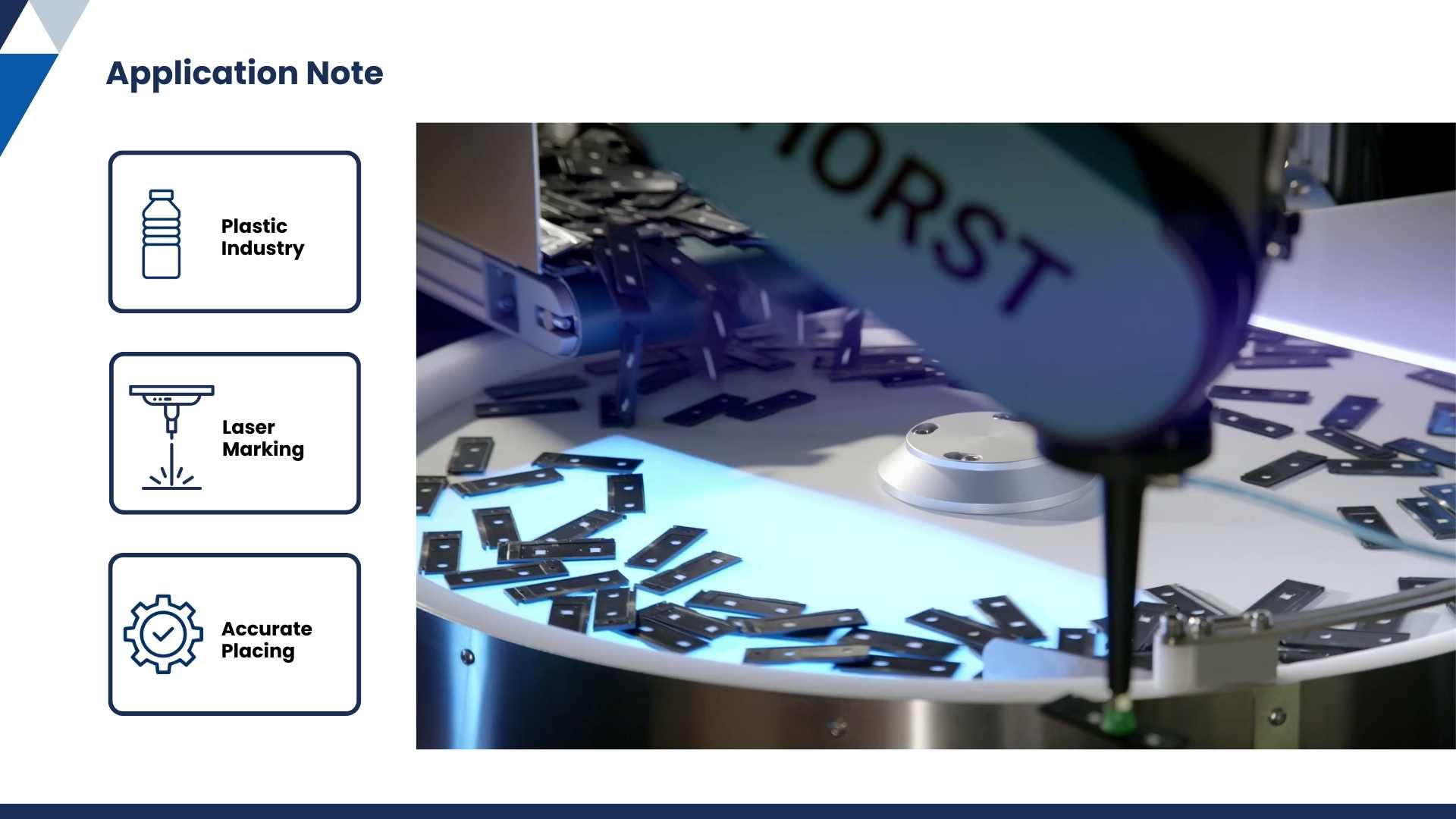

- The system features a conveyor hopper that precisely doses parts into a FlexiBowl® 650, operating in its traditional mode. This setup effectively separates, singulates, and orients the components for further processing.

- An integrated vision system then accurately relays coordinates to a Horst robot, enabling precise pick-and-place operations and positioning the parts for the Trotec Speedmarker 700.

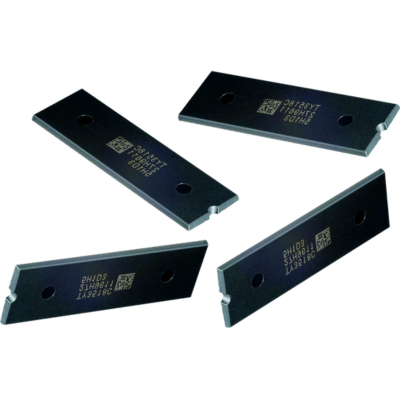

- The Trotec Speedmarker 700 completes the process with high-precision laser marking, ensuring quality and accuracy in the final product.

The Benefit

- Optimal Handling of Delicate Parts: Delicate components are managed efficiently, avoiding any potential damage.

- Performance Enhancement: The automated system has led to an improvement in overall operational performance.

- High-Precision Laser Marking: The system excels at executing laser marking operations with remarkable precision.

- Flexible System for Future Business Developments: The company has equipped itself with a versatile system, ready for reapplication in future business expansions.

Abstract

This case study highlights LaserFIX24's implementation of advanced automation in their laser marking operations, significantly enhancing both the process and product quality. The integration of a FlexiBowl® 650, combined with a precision-driven conveyor hopper, streamlined the handling of various delicate components. This setup, supported by an advanced vision system and a Horst robot, enabled precise pick-and-place operations, culminating in high-precision laser marking with the Trotec Speedmarker 700. The system not only managed parts delicately to avoid damage but also improved performance and accuracy in laser marking. With this automation, LaserFIX24 has equipped itself with a flexible system, ready for future business expansions and diverse project requirements.