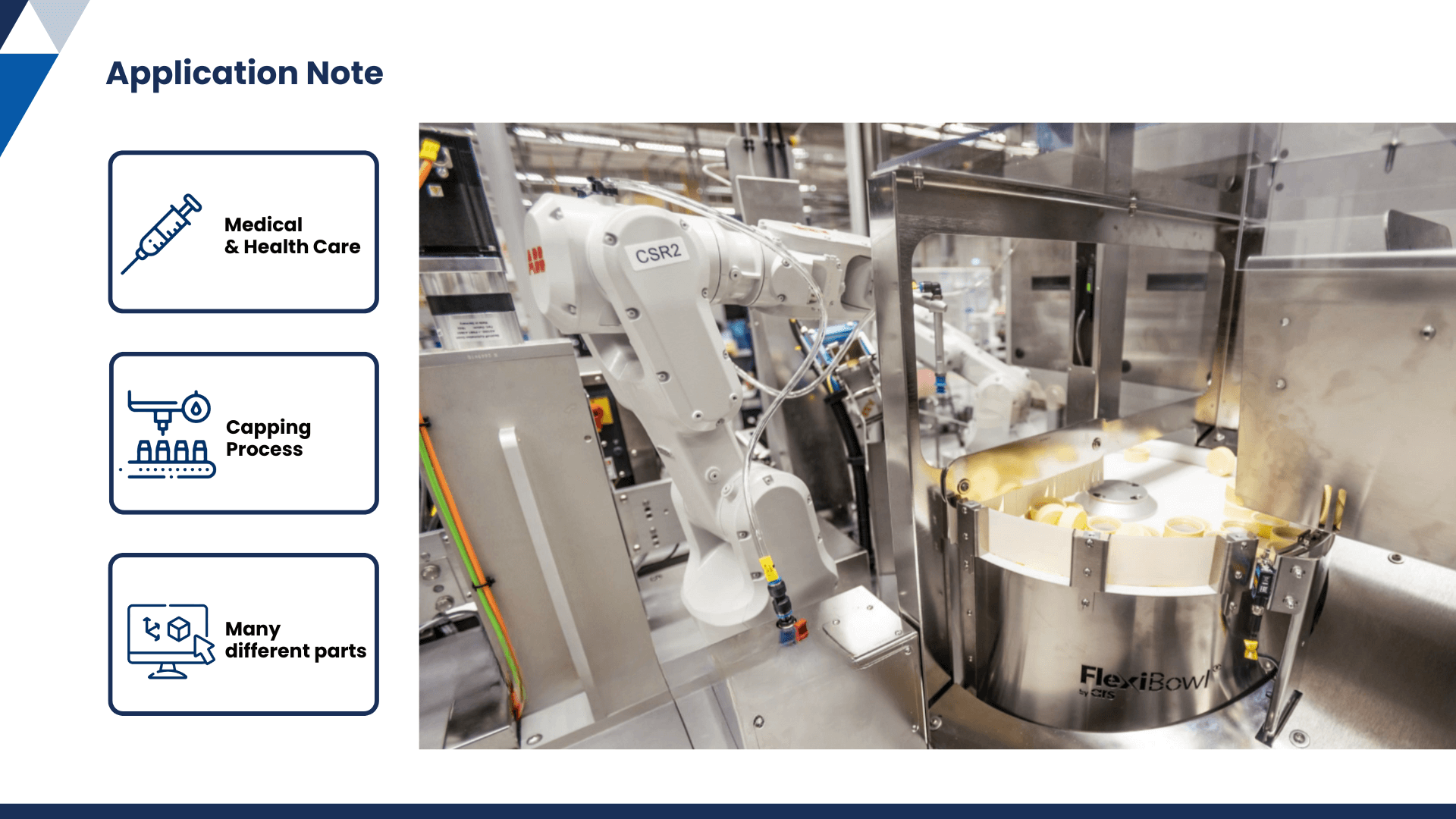

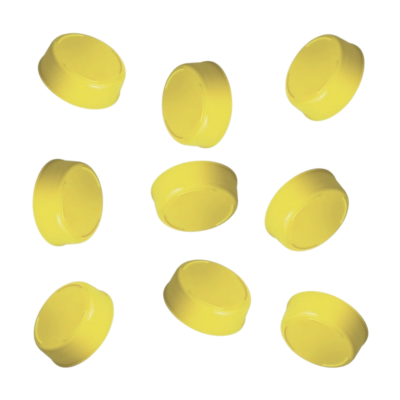

Flexible feeding of medical components in a highly innovative reconfigurable module to handle all shapes and sizes of caps

Case study: modular automation of a medical bottle capping line, improving overall efficiency and flexibility with any component by integrating FlexiBowl® 500 and ABB robots.

Our partner

Graniten has built turn-key solutions since 1992, and today offers products ranging all the way from custom innovations to full-scale production equipment. Global pharmaceutical companies and healthcare suppliers are the testimony to Graniten's exceptional service. At Graniten, the core purpose is to empower its customers and help them improve their production and workflow to continuously enhance patient care and security.

The Challenge

- The task was to develop a solution that feeds caps for medical bottles to be presented to a capping unit.

- The solution must handle all sizes and shapes of caps.

- No format parts allowed.

- The system needs to be easy to clean and empty between batches

The Solution

- Using FlexiBowl® 500 to separate and re-orient the caps so that they can be easily identified in both orientation and position by a vision system, which guides a robot to pick them.

- The system can handle caps regardless of their orientation.

- The unit is easy to access for an operator for refilling and cleaning.

The Benefit

- FlexiBowl® is very effective in separating the caps for the robot.

- The possibility of connecting to a motorized hopper, in order to have a large buffer enabling a longer autonomy.

- Dropping new caps from the bulk feeder can be done in parallel with the robot's picking action, increasing overall efficiency

- The feeding parameters can be optimized for each cap type by using different recipes stored in the machine PLC.

“It was important to find a solution that had no requirement for format parts, which entails no need to reconfigure the machine during the process. This is an important factor in our high technology machines. FlexiBowl® gave us this solution, and thereby contributed to the almost zero changeover time, that is currently a key characteristic of our Graniten Flexline platform solution.”

Daniel Brännwik, Technology Manager, Graniten Group